-

Interchangeability

For the tightly control of production precision, all the size can be maintained at a stable tolerance range.So the interchange type linear guide can keep the same smoothness, preloading and precision when the block arbitrarily assemble on the same type of rail. It is very easy to assemble and repair.

1 -

High Positioning Accuracy

When machine that vectoring by linear guide ,the friction coefficient will be 1/50 of sliding friction coefficient,as the friction method of linear guide is rolling friction, the disparity of dynamic friction and static friction will become smaller, when machine runs, there will be no slipping phenomenon and the positioning accuracy can reach very high.

2 -

Excellent Lubrication Design

Lubrication design patent, can evenly the lubricating grease injection Patent design of Lubricant oil-way can evenly inject lubricating grease to every loo and obtain the optimal lubrication effect under various installation method, it improves the overall running smoothness and service life to achieve the high precision,high reliability and smooth stability of linear motion requirements.

3 -

Four Direction Equal Load Capacity

GTK rail rolling body is to be designed with special pressure angle which make it can bear the same rated load of its radial, anti radial and horizontal direction.

4 -

High Rigidity, High Load

GTK Linear guideway is designed with four columns arc grooves which increase the contact area,compare with two cloumns groove design,it has been greatly improve on the loading capacity, contact stiffness and system rigidity.

5 -

High Precision

GTK linear guideway is produced by high precision special plane which can polyhedrally grind at the same time, detected by laser and other advanced process.all of these guarantee the manufacturing precision of GTK linear guideway.

6 -

Smoothness, Low Noise

The returning device of GTK linear guide adopt a simple and lubricant ball recirculation design with shock resistant circulative accessory —strengthening synthetic resin,the smoothness of the movement is good which achieves a smooth and noiseless linear motion.

7 -

Compact Structure

The section and rigidity of GTK linear guideway attain the most optimal design which is with a small section but high rigidity,thus achieve the purpose of miniaturization of machine tool.

8 -

Easy Installation

The section and rigidity of GTK linear guideway attain the most optimal design which is with a small section but high rigidity,thus achieve the purpose of miniaturization of machine tool.

9 -

With automatic self-aligning capability

Arc groove design of the front combination makes the linear guideway has the ability to automatically adjust the center, even if to give preloading it can absorb installation error, and maintains a high precision, smooth and stable linear motion.

10

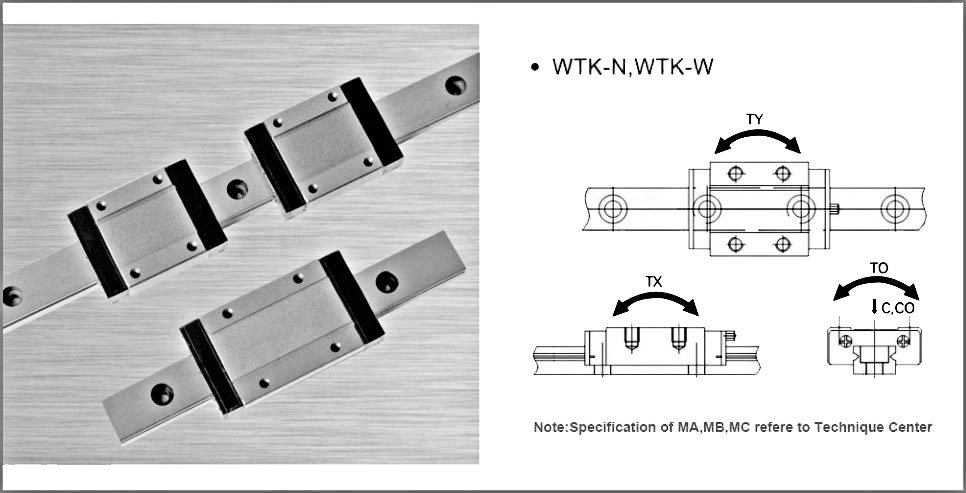

WTK Series (Hiwin MGN MGW)

...

WTK Series (Hiwin MGN MGW)

Features:

Material: Bearing steel

Accuracy Level: N,H

Length of rail : 100mm-4000mm

1. Miniature ball type linear guides are used in linear reciprocating motions to achieve high-precision linear motion.

2. Tiny and light weight design is suitable for miniature equipment.

3.Stable performance, high positioning accuracy and low noise.

4. High precision and

Applications:

Semiconductor equipments, PCB assembly equipments, Medical equipments, Robots, Precision measuring equipments, Office automation equipments, Other miniature sliding mechanism.

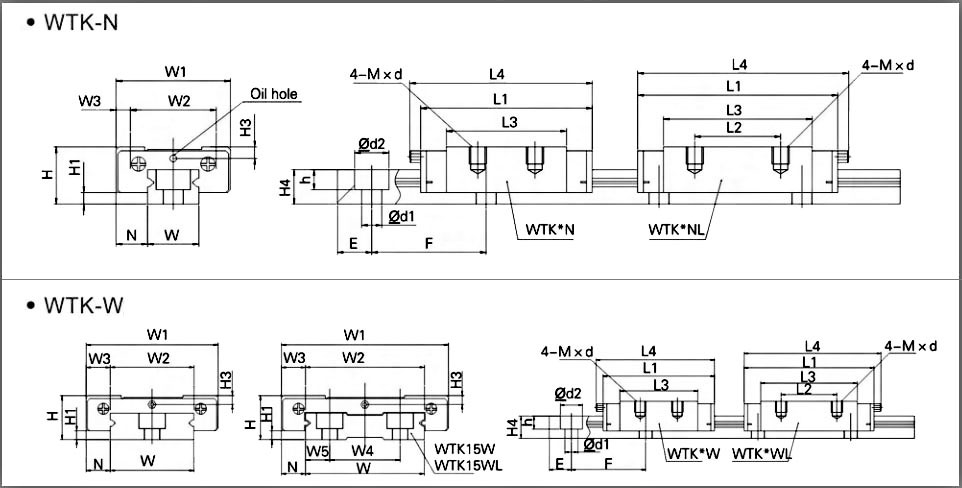

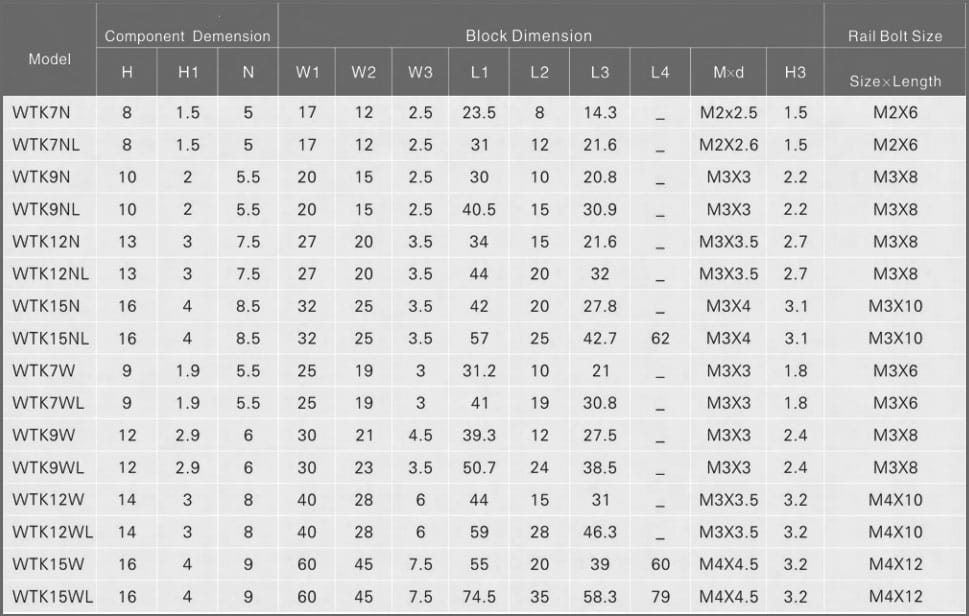

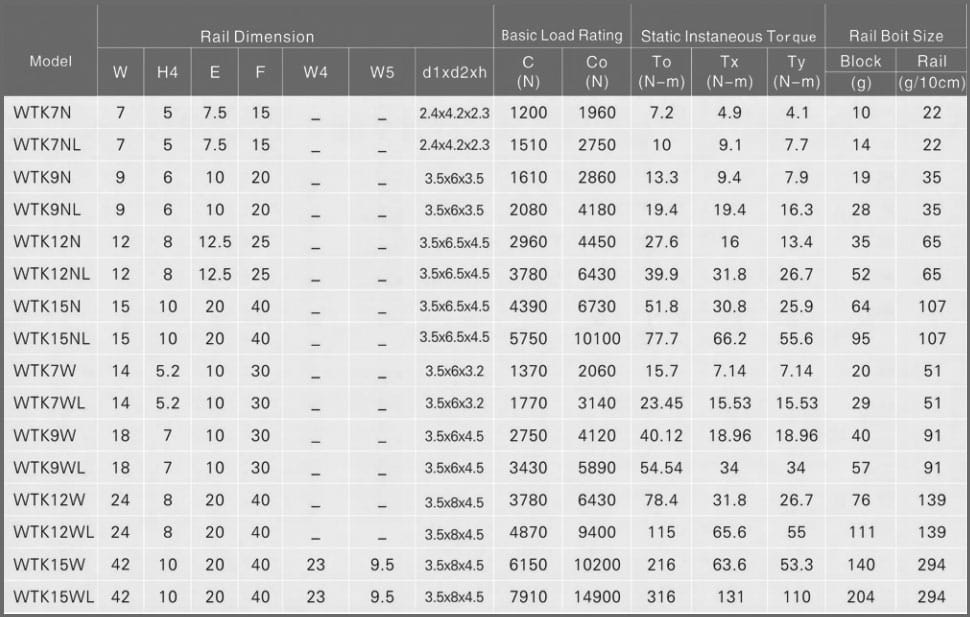

Specifications:

Model: Size 7 to 15, standard and lengthened typeMaterial: Bearing steel

Accuracy Level: N,H

Length of rail : 100mm-4000mm

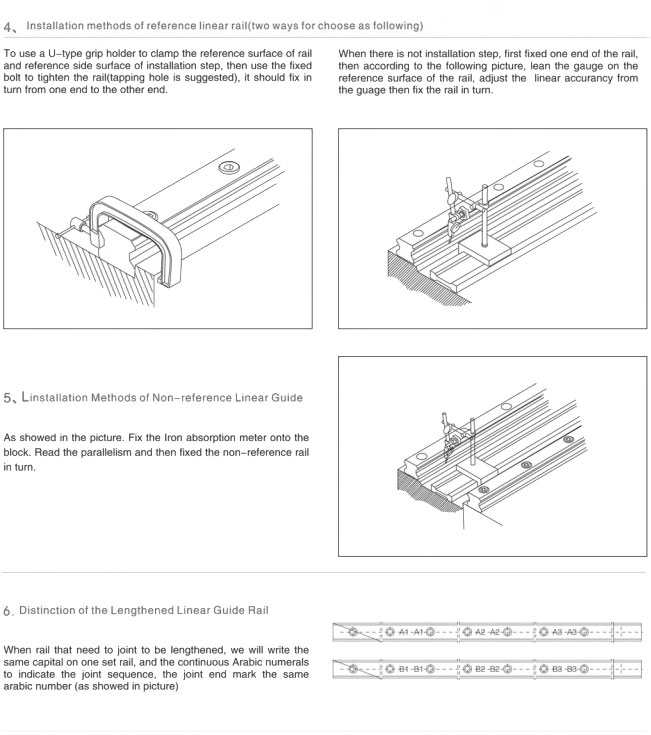

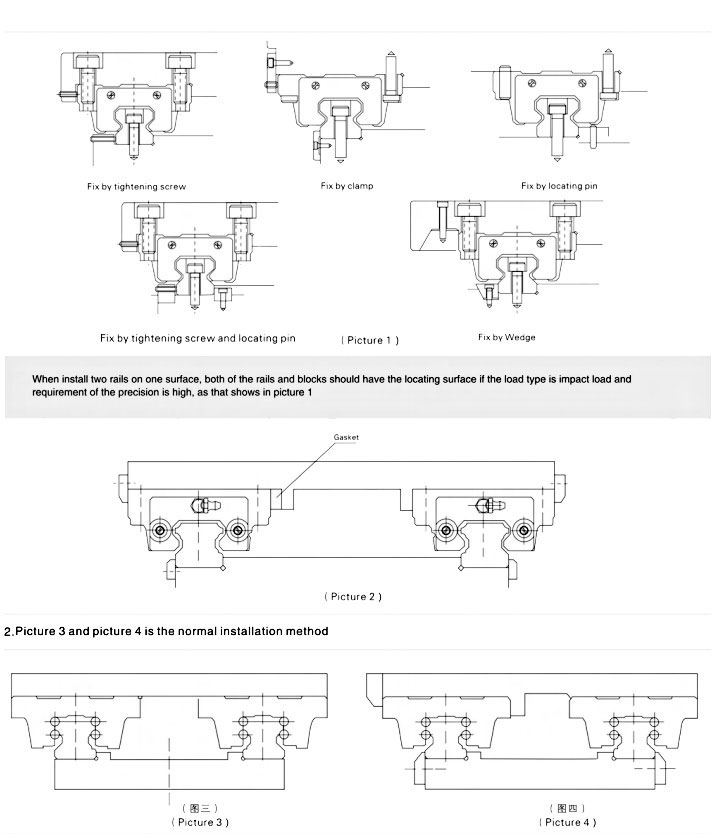

Structure of Connective Datum of Linear Guide

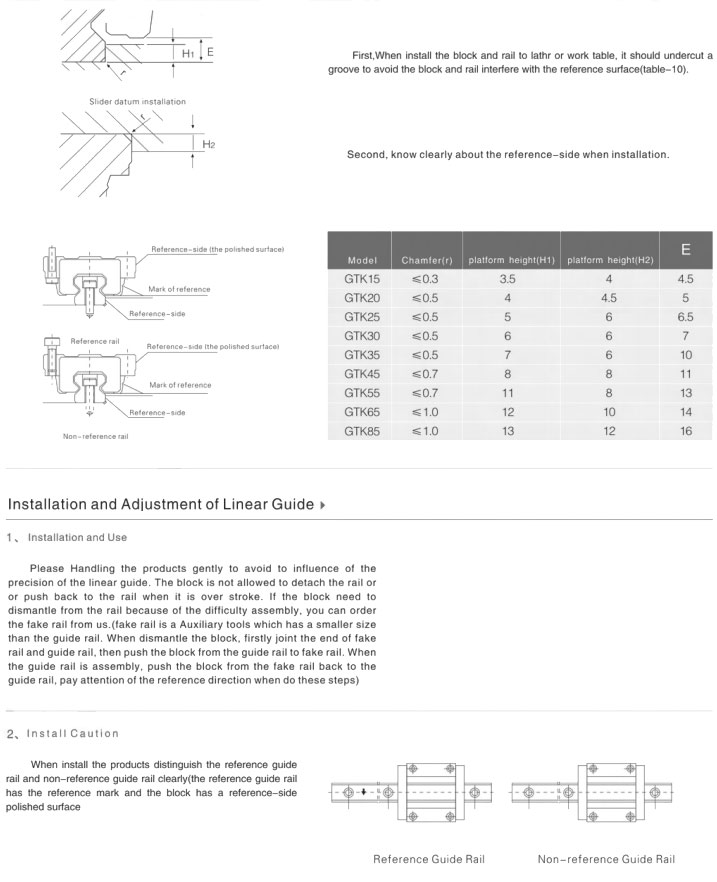

Height and Chamfering of Installation Platform

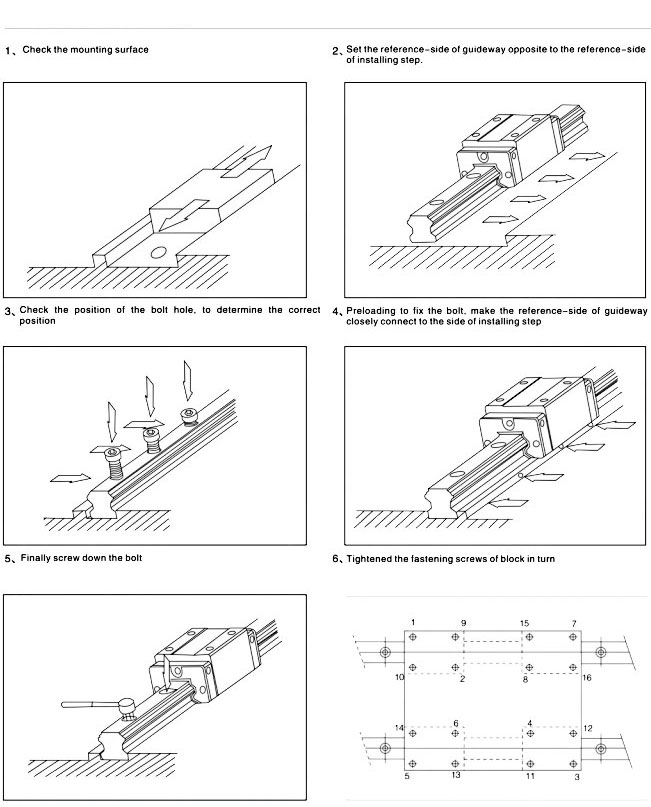

Installation Step of Guideway